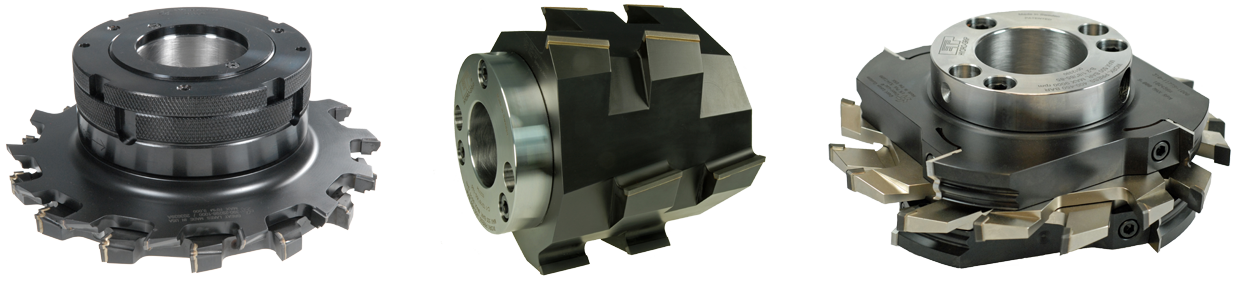

Diamond Tooling

What is Diamond Tooling?

Polycrystalline Diamond, commonly referred to as PCD, is a synthesized, extremely tough inter-grown mass of randomly or orientated diamond crystals bonded to a carbide substrate.

This composite material combines the hardness, abrasion and high-thermal conductivity of diamond with the braze-ability of carbide.

Why use PCD?

High-volume production operations, which do few setups, realize the greatest advantage.

-

The initial cost of PCD Tooling is much higher than carbide. However, greater value is realized overall by savings through the following:

- • Downtime reduction

- • Operating cost reduction

- • Scrap reduction

- • Noise reduction

-

The value of PCD:

- • Proper abrasion resistance characteristics to handle a variety of wood species as well as man-made materials

- • Extended tool life in natural wood

- • Tools maintain their dimensions much more accurately over their working lifetime

- • CNC routers

- • Edge-banders

- • Panel saws

- • Tenoners

- • Moulders

- • Shapers

Best suited applications: